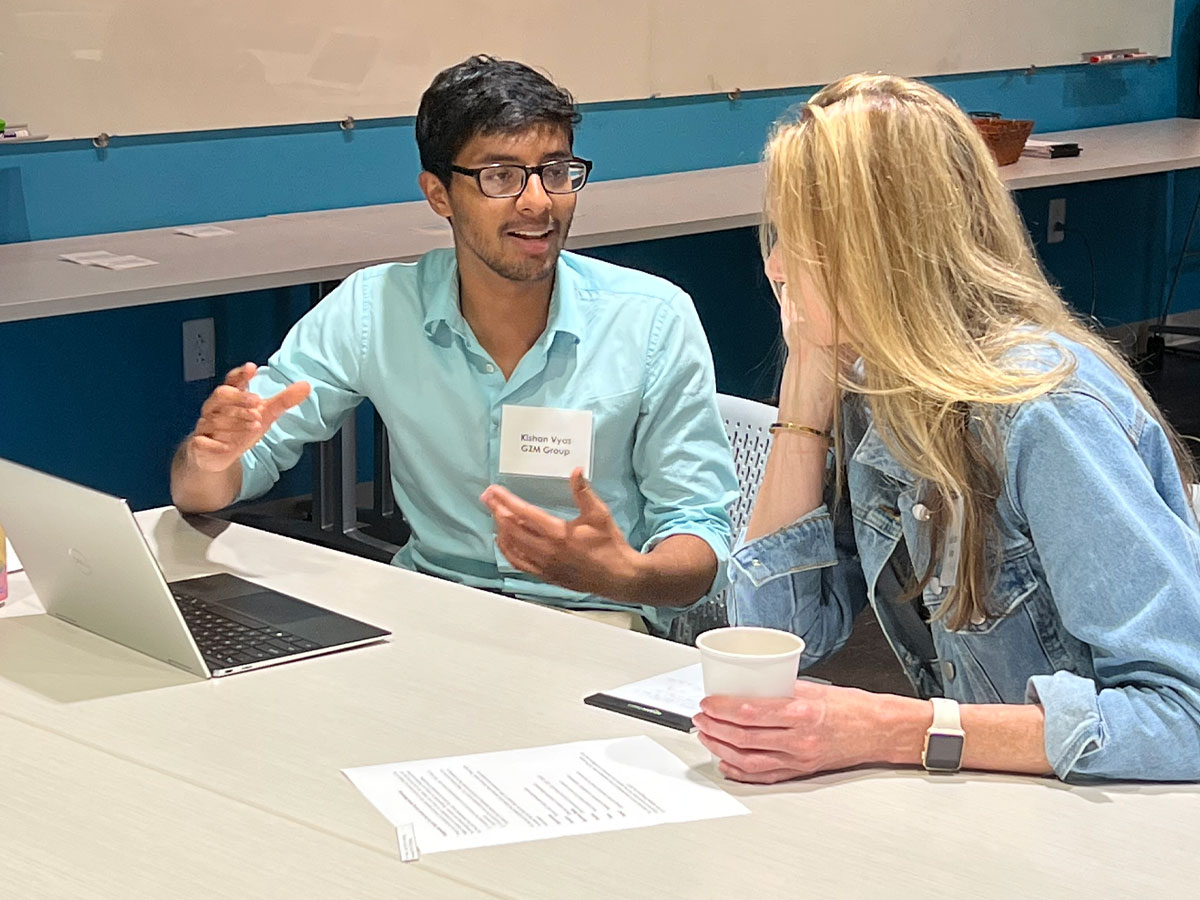

We offer a safe and inclusive space to take risks, connect with local and alumni entrepreneurs, and expand the limits of your curiosity.

Campus

We offer a safe and inclusive space to take risks, connect with local and alumni entrepreneurs, and expand the limits of your curiosity.

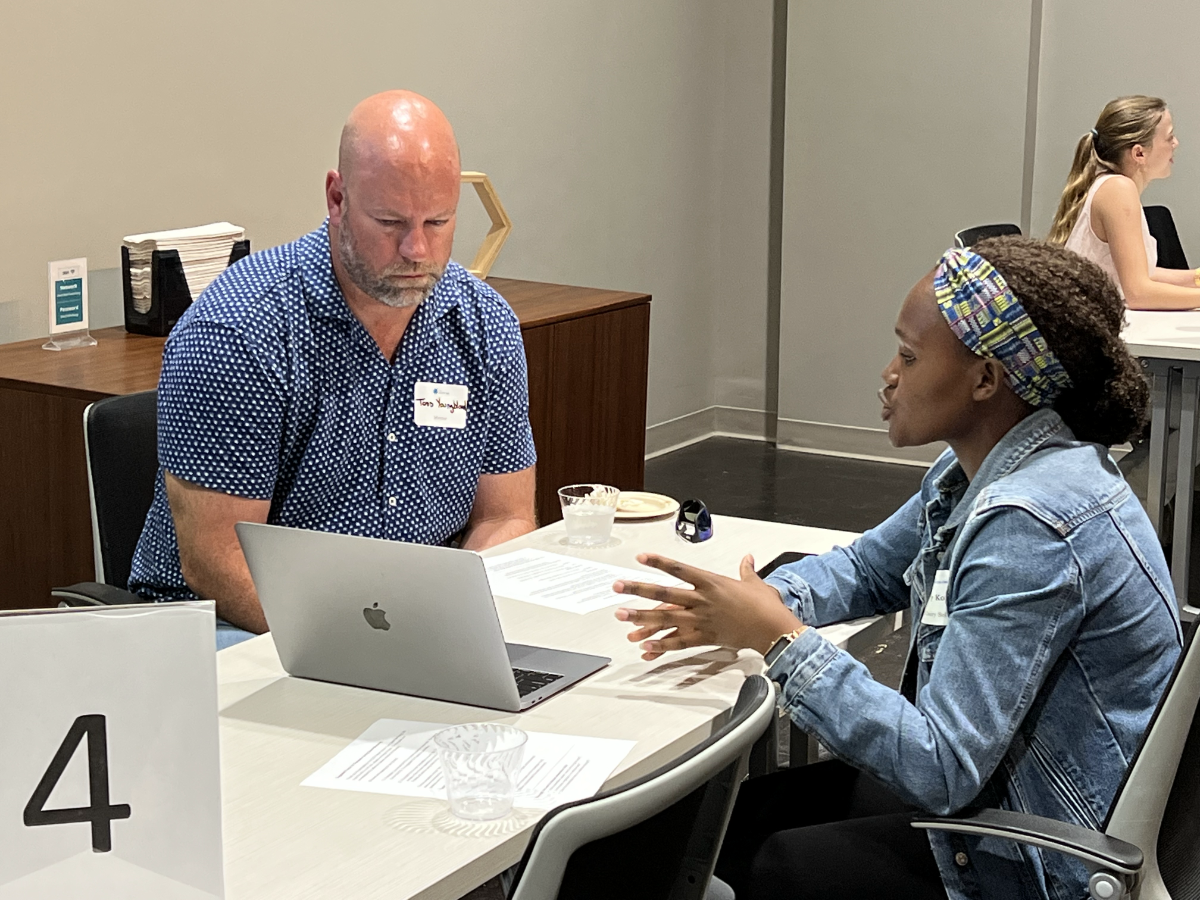

Coworkers

We invite local professionals and entrepreneurs to innovate, learn, and engage with the Hurt Hub@Davidson community in a flexible, collaborative, and productive environment.

Community

We convene innovators and entrepreneurs in the Davidson College community and the Lake Norman region to catalyze innovative solutions to critical problems.

Resources

Fuel your growth and collaboration with The Hurt Hub’s diverse community resources. Unlock your potential through learning, networking, and support.

.

Subscribe to our Newsletter